Filtration solution as clear as glass

Waterco filtration system breathes new life into an old facility

"The best gear was required, which is why we went for the SPDD nozzle plate filters and the EcoPure glass media"

Hydrospec’s managing director

Meeting new regulations

The council awarded the refurbishment project to Willmott Dixon who entrusted Hydrospec Swimming Pool Engineers to carry out the design and the refurbishment of the pools. It was a large job in anyone’s terms.

The facility includes an 880m³ fully tiled main pool with a 3.5m deep diving pool area and 60m³ fully tiled teaching pool. The pool floor alone used 11.5 tonnes of tiles.

All new pipework was installed including new inlets and floor distribution system. Everything was required to meet current standards and guidelines, recalls Hydrospec’s managing director John Cheek.

Plans for the refurbishment also included:

- The addition of a four court sports hall, providing opportunities for a range of indoor sports

- The addition of a double storey-height front extension to create an improved entrance, larger reception area and café with views into the main pool hall

- A 3m diving platform and springboard

- Special needs pool hoists

- A poolside sauna

- Removal of full-height partitions separating the main pool from the learner pool

- Provision of new wet and dry changing areas

- Existing wet change rooms were fully re-equipped

- Retiling of pool surrounds and pool hall walls, and new treatment of other internal finishes

- A 95 station gym

- A new spinning studio adjoining the fitness suite

- Creation of two interconnecting fitness/ dance studios on the first floor

- Replacement of existing roof covering and windows

- New treatment of external elevations, replacing mansard cladding with full height wall treatment

- Alterations to the car park layout and landscaping.

Behind the scenes, an equally impressive works project got underway. “The original filters were two horizontal and one vertical metal fabricated sand filters that had started to corrode and were costly to repair, along with the ongoing maintenance program required with metal fabricated filters,” Mr Cheek states.

“The pools had all new pipework installed along with pool return fittings and all new tiles. The plant room was also totally refurbished.”

Best in class

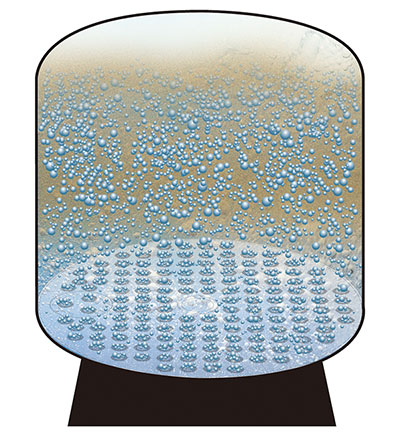

When it came to choosing new filtration equipment, Hydrospec immediately turned to Waterco, which supplied four Micron SPDD2000 Nozzle Plate filters for the main pool and two Micron SPDD1400 for the teaching pool. Waterco’s EcoPure Glass Media was used for both filters, while Waterco Dual pressure gauge panels were also installed.

wound under controlled tension to create a seamless, impervious filter vessel.

“The best gear was required, which is why we went for the SPDD nozzle plate filters and the EcoPure glass media,” Mr Cheek adds. “Nothing else was considered - just the Waterco SPDD filter. We regard it as the best filter in the market as it’s made from GRP material, is easily maintainable, will not corrode and does not require any costly maintenance programs.”

SPDD nozzle plate filters were used over the more conventional lateral commercial filters in order to produce a better standard of fluidisation and sanitisation.

filter practically eliminates failure rates experienced in

most other nozzle plate filters.

plate and nozzle system, which ensures uniform

flow for both filtering and backwashing. This ensures

maximum performance through the media bed

All filters were fitted with the Waterco dual pressure gauge panels to indicate the differential pressure readings across the filter bed for backwashing purposes. The backwash system is fully automatic with a mimic showing the action of all the valve processes for filter, backwash and filter to waste (rinse) facilities.

The result

The Fairfield Leisure Centre reopened in February 2016 to the joy of locals and the admiration of the council. Mr Cheek believes using Waterco’s equipment in the refurbishment was a wise choice. “The water clarity looks great,” he says.

The Micron SPDD Nozzle Plate filters: At a glance

- The SPDD2000 has a flow rate of 21m³/h/m²

- The SPDD1400 has a flow rate of 20m³/h/m²

- Can be used with a combination of in depth filtration techniques, and a variety of media, to provide everything from sediment removal to the elimination of minerals and odours from water

- Easy access for filter media filling and removal

- Fibreglass wound tank, UV and corrosion resistant

- Hydraulically balanced nozzles to maximise water flow and filtration

- Supplied with flanged connections, fitted sight glass and standard service hatch

EcoPure glass media: At a glance

- Removes 30 per cent more material and pollutants than sand, thus saving on backwashing and the resultant water, energy and chemical treatment costs

- Less susceptible to bio-fouling. As the product is heat treated, its surfaces are smooth, so it requires less remedial action and again less chemical treatment to kill pollutants

- Less dense than sand, requiring 20 per cent less media to fill the equivalent filter

- Doesn’t degrade, giving it a longer life span

- Suitable for commercial and domestic use

Download Fairfield Leisure Centre Case Study